AUO's series of next-gen sensing technology offers brand new experiences of human-machine communication in the field of smart applications

AUO utilizes TFT (Array) to expand cutting-edge sensing technology and develop various sensor component products. High-resolution CMUT components with stable quality and mass production capabilities can be used to produce high-resolution ultrasound probes and patch-type probes for administering accurate measurement and physiological monitoring over extended periods on patients.

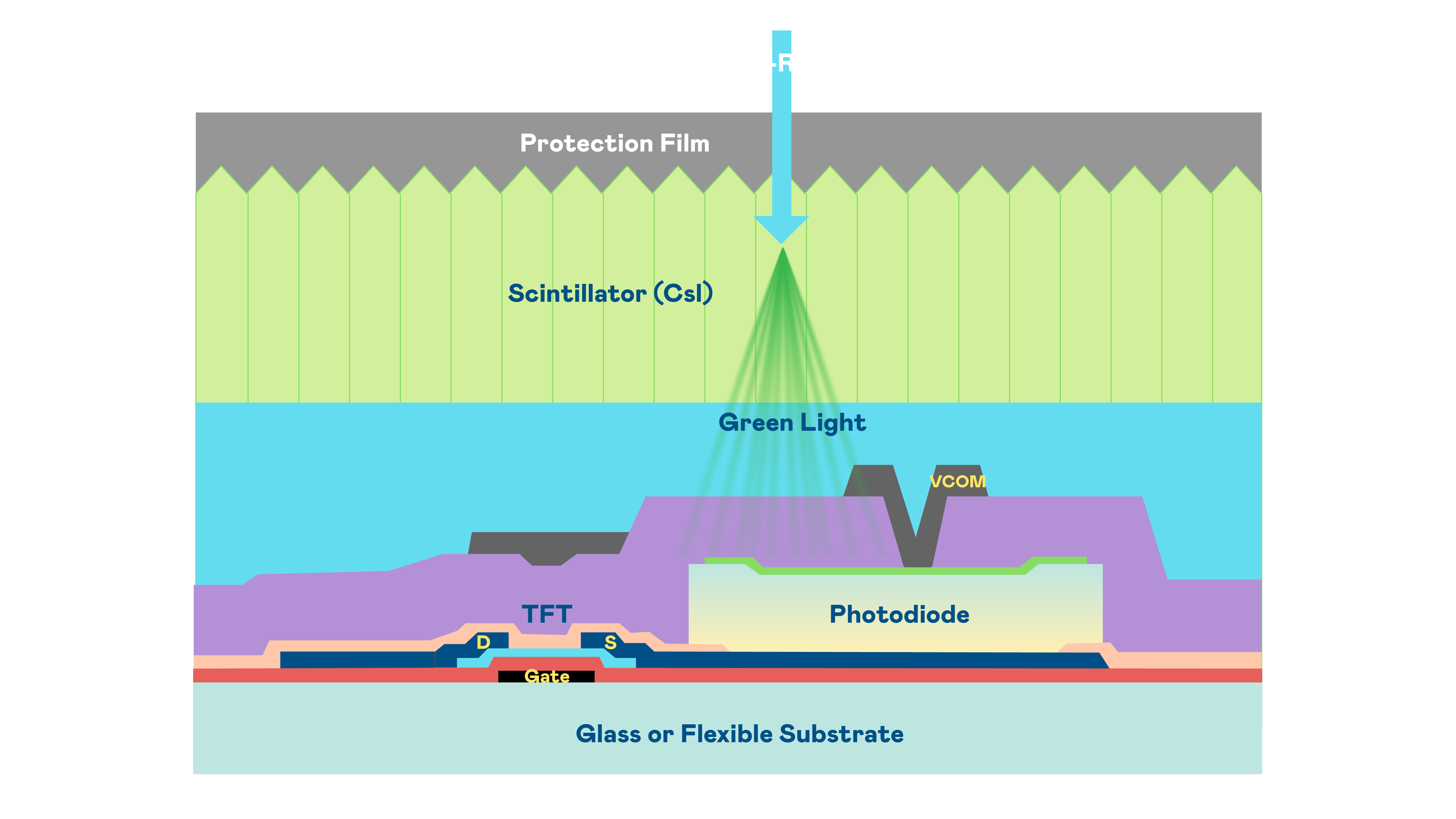

AUO has developed large-size TFT combined with photodiode applications for X-ray imaging, utilizing components with high light sensitivity that can reduce the radiation dose received by the human body during X-ray photography. In addition to glass substrates, flexible substrates can also be selected, making them suitable for portable medical and industrial X-ray imaging sensors.

In addition, AUO's TFT-based full screen optical Fingerprint on Display (FoD) technology allows the entire screen to function as a fingerprint reader with support for multi-finger recognition, thereby enhancing the security and protection of mobile devices. Compared to other technologies that integrate fingerprint recognition and display modules, TFT-based optical fingerprint recognition technology decreases display module thickness and provides a larger sensing area at lower costs, while also improving the recognition success rate.

AUO's X-ray image sensor array uses TFT as readout switches for each pixel, along with photodiodes as the photoelectric conversion elements to detect X-ray image signals.

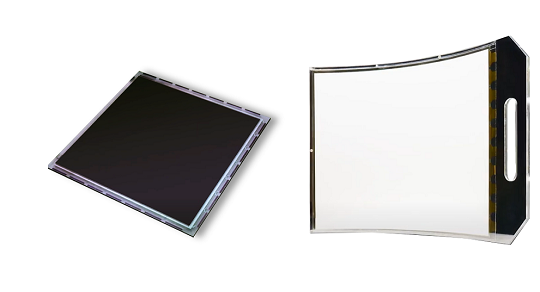

The product technology categories include glass and flexible imaging sensor arrays, a-Si and IGZO TFT technology platforms, as well as X-ray sensor module products that combine scintillator layers with readout chip-on-film (COF) technology.

-

Lightweight, resistant to deterioration and flexible

In addition to glass substrate imaging sensor arrays, AUO has also introduced flexible imaging sensor arrays with plastic substrates to replace glass substrates. For example, the flexible sensor array measuring 17" x 17" weighs less than 70 grams, which represents a 75% reduction in weight compared to glass products. The plastic substrate is not only lightweight but also exhibits characteristics such as impact resistance and durability, making the X-ray detector more suitable for portable applications. Additionally, the flexible imaging sensor array is designed to be bendable, allowing for the creation of a curved X-ray sensor that provides faster and clearer X-ray images for pipeline inspections in non-destructive testing (NDT) fields.

-

IGZO high frame rate, low noise

In addition to a-Si technology, AUO has successfully developed IGZO TFT applications for X-ray sensors. IGZO features high electron mobility, which shortens the charge reading time within pixels, increases the frame rate, reduces motion blur, and provides ultra-high resolution, making it more suitable for dynamic X-ray imaging applications. Furthermore, the unique low leakage characteristics of IGZO and the smaller TFT size enhance the signal-to-noise ratio (SNR) of the sensor array, optimizing image quality.

-

One-stop modular solution

Imaging testing. It helps X-ray sensor customers reduce backend deployment costs and is beneficial for shortening the product development and verification timelines.

Application

-

Curved X-ray sensor

The appearance of many detected objects in X-ray test applications are not flat but curved. Examples include X-ray equipment for detecting the internal state of pipelines and all types of non-destructive testing tools.

-

Portable X-ray equipment

X-ray sensing solutions provided by AUO are lightweight, rugged, and resistant to fall impacts. AUO can assist equipment manufacturers in developing highly rugged, portable X-ray products, including portable detectors used for X-ray diagnostics, industrial non-destructive testing, and explosion-proof products.

-

Contact us for our comprehensive offerings