AUO's series of next-gen sensing technology offers brand new experiences of human-machine communication in the field of smart applications

AUO utilizes TFT (Array) to expand cutting-edge sensing technology and develop various sensor component products. High-resolution CMUT components with stable quality and mass production capabilities can be used to produce high-resolution ultrasound probes and patch-type probes for administering accurate measurement and physiological monitoring over extended periods on patients.

AUO has developed large-size TFT combined with photodiode applications for X-ray imaging. In addition to glass substrates, flexible substrates can also be selected.

For healthcare applications, static X-ray imaging emphasizes high resolution, image consistency, and long-term stability. In contrast, dynamic medical imposes more stringent requirements on sensors, including high-speed readout and low latency.

In industrial applications, X-ray inspection covers non-destructive testing, electronic component analysis, and precision industrial checks. Sensor requirements span high image resolution, inspection speed, and resistance to high X-ray radiation doses.

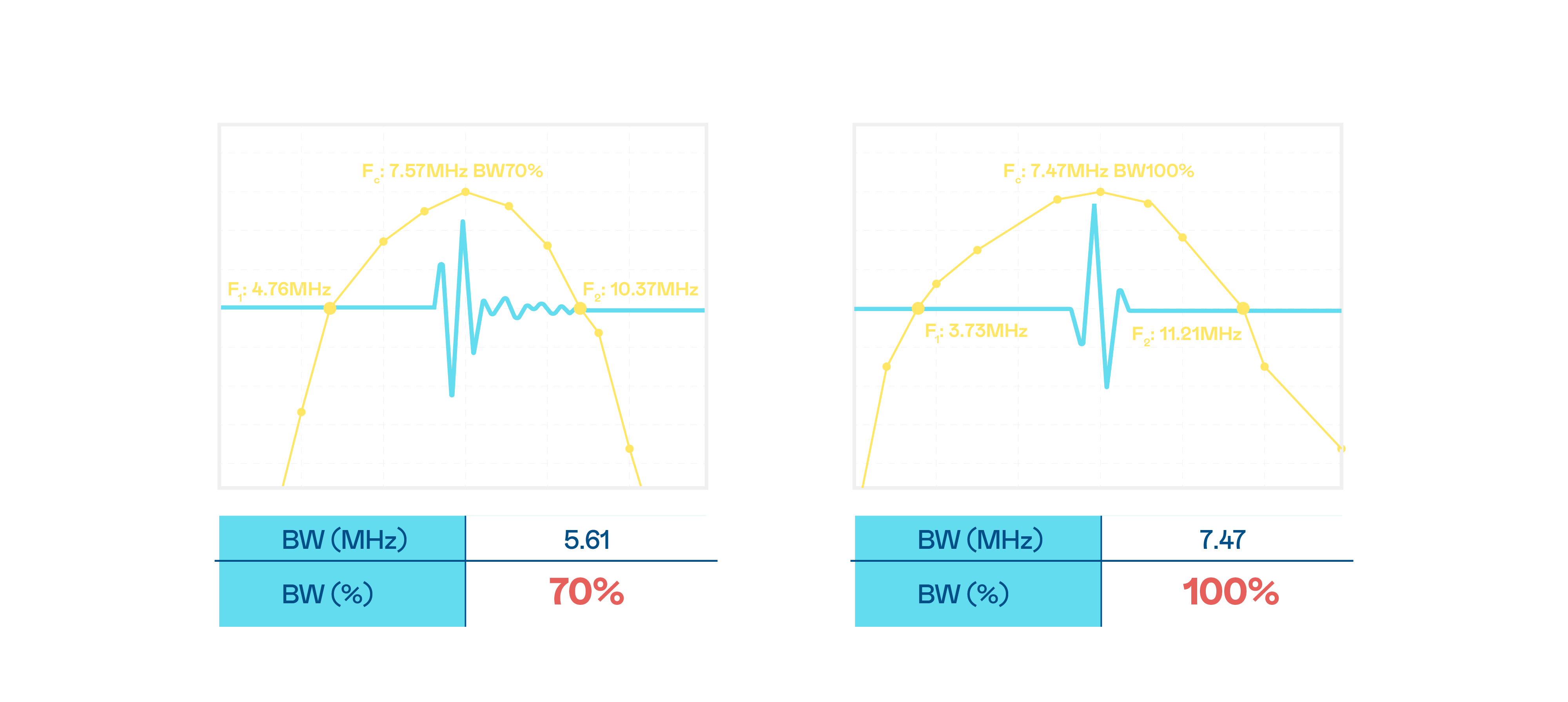

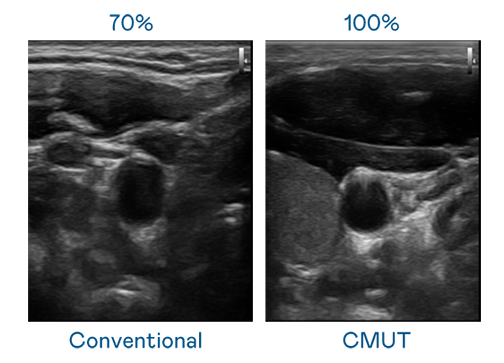

CMUT technology utilizes capacitive MEMS components to generate ultrasound signals. Compared to traditional ceramic piezoelectric technology, the 30% increased bandwidth of CMUT allows for wider ultrasound signals and greatly improved image resolution. This is a crucial technology for achieving medical ultrasounds with high-quality images and promoting the development of precision medicine.

-

Ultra-wide bandwidth offers high-quality images

The image quality of medical ultrasound depends on the signal bandwidth the ultrasound transducer can emit. AUO's CMUT offers high-resolution ultrasound signals with ultra-wide bandwidth and high sensitivity for more delicate image texture and details to help ultrasound medical examiners reduce time on interpreting and diagnosing based on precise medical images.

-

MEMS can facilitate mass production

MEMS processes allow for stable mass production in batches by improving the disadvantages of traditional piezoelectric probes, such as poor yield and insufficient production capacity. More importantly, it allows the assembly of components into all types of array transducers depending on the application; for instance, standard ultrasound scanners utilize linear arrays, while 3D ultrasound scanners utilize 2D phased arrays. In addition, CMUT can be utilized to produce patch or thin ultrasound probes used in physiological monitoring over extended periods.

.png)

Application

-

Ultrasound probe

Medical ultrasound scanner technology has been widely adopted in medicine, and various functions have been derived by combining ultrasound systems with different probes. AUO's CMUT technology is assembled to satisfy the specification requirements of various probes, such as classic linear array probes or 2D phased array probes required in 3D ultrasounds. AUO also offers CMUT components with a frequency above 20MHz for ultra-high resolution image requirements.

-

Ultrasound patch

Capacitive MEMS transducers can significantly decrease the size of ultrasound components and break free from traditional ultrasound probes' aesthetic or size restrictions. The result is thinner or ultra-thin devices, similar to patches. Patch-type ultrasounds are crucial for applications requiring monitoring for extended periods, such as monitoring carotid blood flow to detect signs of stroke or monitoring for collapsed tongues to prevent obstructive apnea.

-

Contact us for our comprehensive offerings