With the announcement of 33rd (2025) Taiwan Excellence Awards, AUO shines once again by securing Silver Awards for the “AUO Smart Cockpit 2024”, the Solar PV Module Cleaning Robot “SunCleanBots” and the Solar power monitoring system “SunVeillance”, underscoring its commitment to technological and quality excellence.

Additionally, AUO has nominated eight products in total, all products across advanced displays, energy solutions, in-vehicle HMI solutions, and smart manufacturing were recognized with Taiwan Excellence Award other than the Silver winning products, highlighting AUO’s capability in enhancing user experiences through innovative solutions.

The mark of Taiwan Excellence has become a common brand for Taiwanese products with innovative values, renowned in the international market for the excellence and quality that are associated with the mark.

|

Explore more about AUO’s award winning products: Taiwan Excellence Silver Award The AUO Smart Cockpit 2024 enables automakers to install a series of display HMI solutions, including an advanced pillar-to-pillar curved AmLED® display across the entire instrument panel of the vehicle. This display can house all elements of the driving and infotainment system, connecting drivers and passengers with relevant information and links to infrastructure. Cameras and sensors embedded in the display facilitate the integration of innovative applications. Additionally, the passenger screen's built-in active privacy mode is designed to prevent driver distraction, contributing to a safer driving experience.

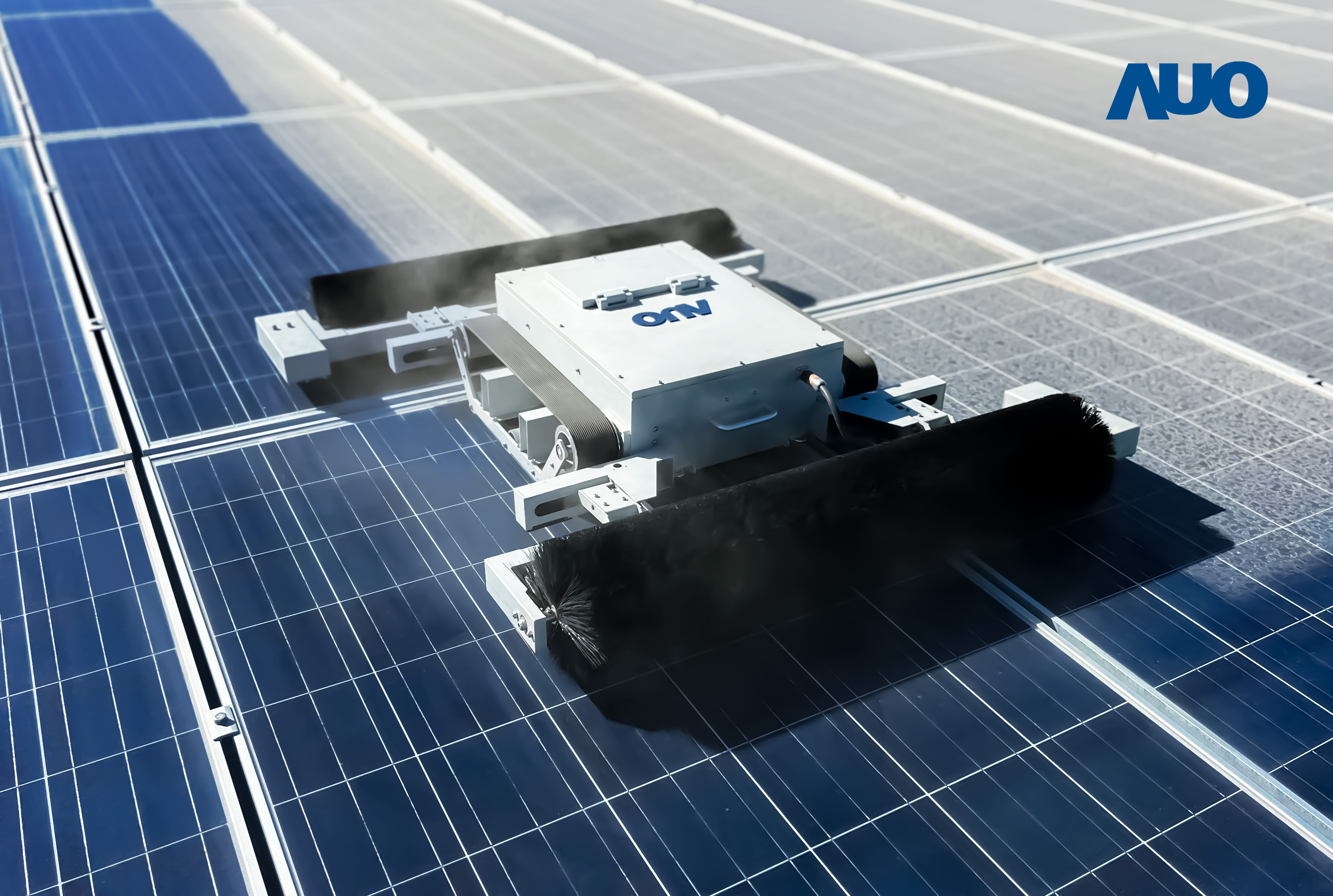

Regular cleaning of modules is extremely critical for solar energy plants as it impacts module lifespan, energy generation, and can even affect general return on investment. However, the labor and water costs are extremely high due to the large areas of solar energy plants, not to mention time consuming. SunCleanBots can clean by moving on solar energy arrays, greatly increasing the safety of workers. Through a combination of sensors and big data analysis, modules can be cleaned according to weather conditions and other parameters to reduce operation costs.

In human-machine collaboration and real-time AI surveillance technologies, the AUO SunVeillance PV Smart Cloud System allows defective modules to be located and repaired. Other advantages include lower workforce costs, improved inspection quality, and higher power output. This energy solutions integrates 4 systems for efficient renewable energy management: SunVeillance, DREAMS, Green Energy Trading Platform, and PowerVeillance, providing a comprehensive and efficient renewable energy management platform that covers the entire process of generation, consumption, and trading of electricity.

Taiwan Excellence Award The 60 inch High-transparent Micro LED Display developed by AUO features a full-screen brightness of 600 nits, a transparency rate of over 60 percent, and an exceptional wide color gamut exceeding NTSC 110 percent, allowing flexible applications in various settings, such as smart windows for commercial displays, creating innovative smart living experiences.

The Rollable RSE is developed for smart cockpit, this innovative technology harnesses the flexible and bendable advantages of Micro LED displays, enables the display to be rolled up and concealed in the front seat backrest, creating a spacious and adaptable passenger space. The Rollable RSE enhances the passenger experience with its high-definition, clear, and bright Micro LED display, providing an interactive and sensory experience while also incorporating personalized design elements.

The Interactive Transparent Window is also developed for smart cockpit, it incorporates the integration of high-transparency Micro LED displays into the side windows of vehicles, providing touch functionality for in-vehicle entertainment, online video conferencing, and the display of safety warning information.

The AMR 150M is developed to tackle production inefficiencies and labor shortages, boosting productivity and reducing downtime by adopting the modular design which includes forklifts, lifts, conveyors, and robotic arms. By following high safety standards, it enhances productivity and ensures quality delivery from the production line.

The System features the integration of SPIIDER D Series from AUO Digitech and APES (Anomaly detection & Prognostic of Equipment System), which allows users to take timely actions for equipment maintenance, enhancing production efficiency and reducing the risk of equipment failure. The SPIIDER D Series serves as an IoT data acquisition device, while APES is a predictive monitoring system. By installing sensors and capturing data with the SPIIDER device, the data is uploaded to APES, which then calculates and predicts the condition of the machinery.

|

|